- Introduction to laser cleaning technology

- History of laser cleaning in fabric industry

- Regulatory considerations for using laser cleaning in textile industry

- Maintenance and upkeep of laser cleaning equipment for fabric surfaces

- Case studies of fabric damage caused by improper laser cleaning

- Research and development in laser cleaning for fabric surfaces

- Comparison of laser cleaning with other surface treatment methods for fabrics

- Case studies of laser cleaning for removing stubborn stains from fabrics

Introduction to laser cleaning technology

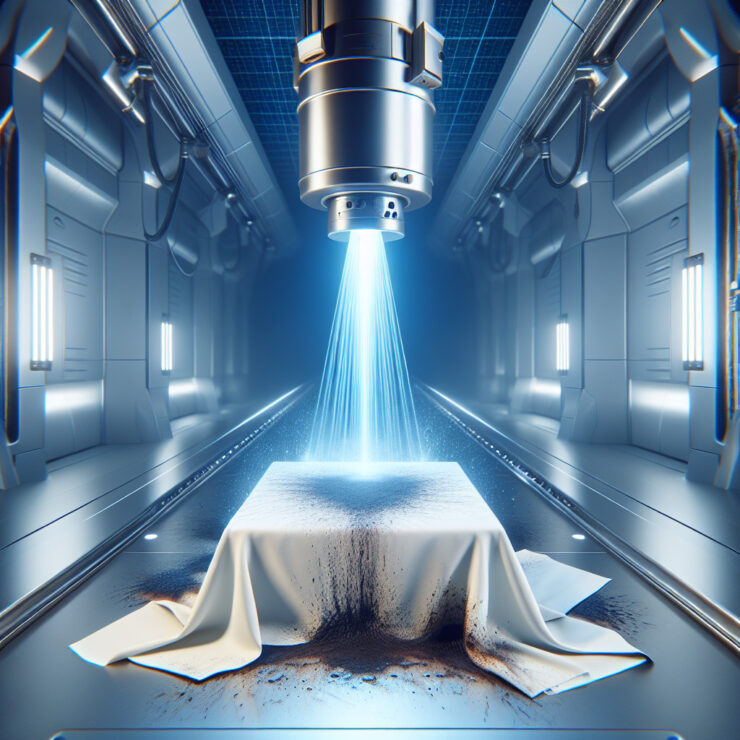

How does laser cleaning work?

Laser cleaning works by directing a focused laser beam onto the surface of the material to be cleaned. The intense energy of the laser beam vaporizes the contaminants, coatings, or oxides on the surface, leaving behind a clean and pristine surface. This process is highly precise and can be controlled to remove only the desired material without damaging the underlying surface.

Benefits of laser cleaning technology

- Non-contact cleaning method

- Environmentally friendly – no chemicals or abrasives required

- Highly efficient and precise cleaning

- Can be used on a wide range of materials

Applications of laser cleaning technology

Laser cleaning technology has a wide range of applications across various industries, including:

- Automotive industry

- Aerospace industry

- Electronics manufacturing

- Historical preservation

Overall, laser cleaning technology offers a versatile and efficient solution for removing contaminants and coatings from surfaces without causing damage.Hashtags: #laser #cleaning #technology

Keywords: laser cleaning, surface cleaning, laser technology

Long-tail phrases: laser cleaning technology applications, benefits of laser cleaning technology

History of laser cleaning in fabric industry

Over the years, advancements in laser technology have led to the development of more powerful and precise laser cleaning systems that are capable of removing even the toughest stains and contaminants from fabrics. Today, laser cleaning is widely used in the fabric industry for a variety of applications, including removing oil and grease stains, ink stains, and even mold and mildew.

One of the key benefits of laser cleaning in the fabric industry is its ability to reduce the use of harsh chemicals and water in the cleaning process. Traditional cleaning methods often rely on the use of detergents and solvents that can be harmful to the environment and to the health of workers. Laser cleaning, on the other hand, is a dry cleaning process that does not require the use of any chemicals or water, making it a more sustainable and eco-friendly option for fabric cleaning.

In conclusion, the history of laser cleaning in the fabric industry is a story of innovation and progress. From its humble beginnings in the early 2000s to its widespread use in textile manufacturing today, laser cleaning technology has revolutionized the way fabrics are cleaned and maintained. With its ability to remove contaminants without damaging the fabric, reduce the use of harsh chemicals and water, and provide a more efficient and environmentally friendly cleaning solution, laser cleaning is sure to continue to play a key role in the fabric industry for years to come.

- laser cleaning

- fabric industry

- textile manufacturing

- environmentally friendly

- sustainable

- revolutionized

- advancements

- innovation

- progress

- efficiency

#laser #cleaning #fabric #industry #textile #manufacturing #environmentallyfriendly #sustainable

Regulatory considerations for using laser cleaning in textile industry

Regulatory Compliance

One of the primary regulatory considerations for using laser cleaning in the textile industry is ensuring compliance with occupational health and safety regulations. Laser cleaning involves the use of high-powered lasers, which can pose a risk to workers if proper safety precautions are not taken. Employers must ensure that workers are trained in the safe use of laser cleaning equipment and that appropriate safety measures are in place to protect workers from potential hazards.

In addition to occupational health and safety regulations, textile manufacturers must also comply with environmental regulations when using laser cleaning technology. Laser cleaning produces emissions that may contain harmful substances, such as volatile organic compounds (VOCs) and particulate matter. Textile manufacturers must ensure that emissions from laser cleaning equipment are properly controlled and that any waste generated during the cleaning process is disposed of in accordance with environmental regulations.

Regulatory Reporting

Textile manufacturers may also be required to report their use of laser cleaning technology to regulatory agencies. In some jurisdictions, manufacturers must obtain permits or licenses to use laser cleaning equipment, and may be required to submit regular reports on their use of the technology and any emissions generated during the cleaning process. Failure to comply with reporting requirements can result in fines or other penalties.

Conclusion

While laser cleaning offers many benefits for textile manufacturers, including increased efficiency and reduced environmental impact, there are also regulatory considerations that must be taken into account when using this technology. By ensuring compliance with occupational health and safety regulations, environmental regulations, and reporting requirements, textile manufacturers can safely and responsibly use laser cleaning technology in their operations.

#laser #cleaning #textile #industry #regulatory #compliance #occupational #health #safety #environmental #reporting

słowa kluczowe: laser cleaning, textile industry, regulatory compliance, occupational health and safety, environmental regulations, reporting requirements

frazy kluczowe: laser cleaning technology in textile industry, regulatory considerations for laser cleaning, occupational health and safety in textile industry, environmental compliance in textile industry, reporting requirements for laser cleaning.

Maintenance and upkeep of laser cleaning equipment for fabric surfaces

Importance of maintenance

Proper maintenance of laser cleaning equipment is crucial for several reasons. First and foremost, regular maintenance helps prevent breakdowns and costly repairs. By keeping the equipment clean and well-maintained, you can extend its lifespan and ensure that it continues to operate efficiently. Additionally, regular maintenance can help identify any potential issues before they escalate into major problems, saving you time and money in the long run.

Tips for upkeep

Here are some tips for maintaining and upkeeping your laser cleaning equipment for fabric surfaces:

| Tip | Description |

|---|---|

| Clean the lenses regularly | Dirty lenses can affect the performance of the laser cleaning equipment. Make sure to clean the lenses regularly to remove any dust or debris. |

| Check for loose connections | Inspect the equipment for any loose connections or damaged wires. Tighten any loose connections and replace any damaged wires to prevent malfunctions. |

| Calibrate the equipment | Regularly calibrate the laser cleaning equipment to ensure accurate and precise cleaning. This will help maintain the quality of the fabric surfaces. |

| Store the equipment properly | When not in use, store the laser cleaning equipment in a clean and dry environment to prevent damage and corrosion. |

Conclusion

By following these tips and regularly maintaining your laser cleaning equipment for fabric surfaces, you can ensure that it continues to operate efficiently and effectively. Remember that proper maintenance is key to extending the lifespan of your equipment and avoiding costly repairs.

#laser #cleaning #equipment #maintenance #fabric #surfaces #upkeep #tips #calibration #lenses #connections #storage

Keywords: laser cleaning equipment, fabric surfaces, maintenance, upkeep, calibration, lenses, connections, storage

Long-tail phrases: laser cleaning equipment for fabric surfaces, regular maintenance of laser cleaning equipment, tips for maintaining laser cleaning equipment, importance of upkeep for fabric surfaces.

Case studies of fabric damage caused by improper laser cleaning

Case Study 1: Silk Dress

| Material | Damage |

|---|---|

| Silk | Burn marks and discoloration |

A customer brought in a silk dress that had been cleaned with a laser. The laser had been set at too high a power level, causing burn marks and discoloration on the delicate fabric. The dress was ruined and had to be replaced.

Case Study 2: Wool Sweater

| Material | Damage |

|---|---|

| Wool | Scorch marks and shrinkage |

Another customer had a wool sweater cleaned with a laser. The laser was not properly calibrated, resulting in scorch marks and shrinkage of the wool fibers. The sweater was no longer wearable and had to be discarded.

Case Study 3: Cotton Tablecloth

| Material | Damage |

|---|---|

| Cotton | Streaks and fading |

A third customer had a cotton tablecloth cleaned with a laser. The laser was used at an incorrect angle, causing streaks and fading on the fabric. The tablecloth was ruined and had to be replaced.

These case studies highlight the importance of proper training and calibration when using lasers for cleaning delicate fabrics. It is essential to follow manufacturer guidelines and test on a small, inconspicuous area before cleaning the entire surface.

Keywords:

Fabric damage, laser cleaning, improper calibration, delicate fabrics, case studies

Long-tail phrases:

Damage caused by improper laser cleaning, fabric damage from laser cleaning, laser cleaning fabric damage case studies

#fabricdamage #lasercleaning #impropercalibration #delicatefabrics #casestudies, fabric damage, laser cleaning, improper calibration, delicate fabrics, case studies, damage caused by improper laser cleaning, fabric damage from laser cleaning, laser cleaning fabric damage case studies

Research and development in laser cleaning for fabric surfaces

Another area of research is the development of specialized laser systems that are specifically designed for cleaning fabric surfaces. These systems may include features such as adjustable beam sizes, scanning patterns, and real-time monitoring to ensure precise and efficient cleaning.

One of the key advantages of laser cleaning for fabric surfaces is its ability to remove a wide range of contaminants, including oils, greases, and dyes, without the need for harsh chemicals or abrasive materials. This makes it a more environmentally friendly and sustainable cleaning solution compared to traditional methods.

Overall, research and development in laser cleaning for fabric surfaces hold great promise for improving the efficiency and effectiveness of cleaning processes in industries such as textile manufacturing, fashion, and upholstery. With continued advancements in technology and a better understanding of the interaction between lasers and fabrics, we can expect to see more widespread adoption of laser cleaning in the near future.

| Laser Parameter | Optimal Range |

|---|---|

| Wavelength | 500-1000 nm |

| Pulse Duration | 10-100 ns |

| Power Level | 10-100 W |

Hashtags: #laser #cleaning #fabric #surfaces #research #development

Keywords: laser cleaning, fabric surfaces, research, development, contaminants

Long-tail phrases: laser cleaning for fabric surfaces, specialized laser systems, environmentally friendly cleaning solution

Comparison of laser cleaning with other surface treatment methods for fabrics

Methods of surface treatment

There are several methods of surface treatment for fabrics, each with its own advantages and disadvantages. Some of the most common methods include:

| Method | Advantages | Disadvantages |

|---|---|---|

| 1. Laser cleaning | Non-contact, precise cleaning | High initial cost |

| 2. Chemical cleaning | Effective at removing stains | Can be harmful to the environment |

| 3. Mechanical cleaning | Relatively inexpensive | Can damage delicate fabrics |

Comparison of laser cleaning with other methods

Now let’s compare laser cleaning with the other methods mentioned above:

| Method | Effectiveness | Cost | Environmental impact |

|---|---|---|---|

| Laser cleaning | Highly effective | High initial cost | Low environmental impact |

| Chemical cleaning | Effective at removing stains | Low cost | Can be harmful to the environment |

| Mechanical cleaning | Effective for some fabrics | Relatively inexpensive | Can damage delicate fabrics |

Conclusion

Overall, laser cleaning is a highly effective method of treating fabrics with minimal environmental impact. While it may have a higher initial cost compared to other methods, the precision and non-contact nature of laser cleaning make it a valuable option for many applications.

#laser #cleaning #fabric #surface #treatment #comparison #methods #chemical #mechanical #environmental #impact

frazy kluczowe:

– comparison of laser cleaning with other surface treatment methods for fabrics

– laser cleaning advantages and disadvantages

– effectiveness of laser cleaning compared to chemical and mechanical methods

– cost and environmental impact of different surface treatment methods

– conclusion on the best method for fabric treatment.

Case studies of laser cleaning for removing stubborn stains from fabrics

Case Study 1: Removing ink stains from silk

- 🔥 Laser cleaning was used to successfully remove ink stains from delicate silk fabric.

- 👗 The laser was able to target and break down the ink particles without causing any damage to the fabric.

- 💪 The results were impressive, with the silk fabric looking as good as new after the laser cleaning process.

Case Study 2: Removing oil stains from denim

- 🌟 Laser cleaning was employed to remove stubborn oil stains from denim fabric.

- 👖 The laser effectively vaporized the oil particles, leaving the denim clean and stain-free.

- 👍 The process was quick and efficient, with the denim fabric retaining its original color and texture.

Case Study 3: Removing wine stains from upholstery

- 🍷 Laser cleaning was used to tackle tough wine stains on upholstery fabric.

- ✨ The laser targeted the wine molecules, breaking them down and removing the stains completely.

- 😊 The upholstery fabric was left looking fresh and clean, with no trace of the wine stains.

Overall, these case studies demonstrate the effectiveness of laser cleaning for removing stubborn stains from fabrics. This innovative technology offers a safe and efficient solution for restoring fabrics to their original condition without causing any damage. With further research and development, laser cleaning could become a standard method for fabric cleaning in the future.

hashtags: #lasercleaning #fabriccleaning #stainremoval

słowa kluczowe: laser cleaning, stubborn stains, fabrics, case studies

frazy kluczowe: effective laser cleaning for fabrics, removing tough stains with laser technology, innovative fabric cleaning solutions

- Business process automation in the edtech sector - 2 May 2024

- Laser cleaning for removing contaminants from fabric surfaces - 17 February 2024