- Introduction to laser cleaning technology

- Benefits of using laser cleaning for metal surfaces

- Types of contaminants that can be removed with laser cleaning

- Cost analysis of laser cleaning compared to other cleaning methods

- Environmental impact of laser cleaning

- Advantages of laser cleaning over chemical cleaning

- Laser cleaning as a non-destructive method for preserving historical artifacts

- Benefits of laser cleaning for improving adhesion of coatings on metal surfaces

Introduction to laser cleaning technology

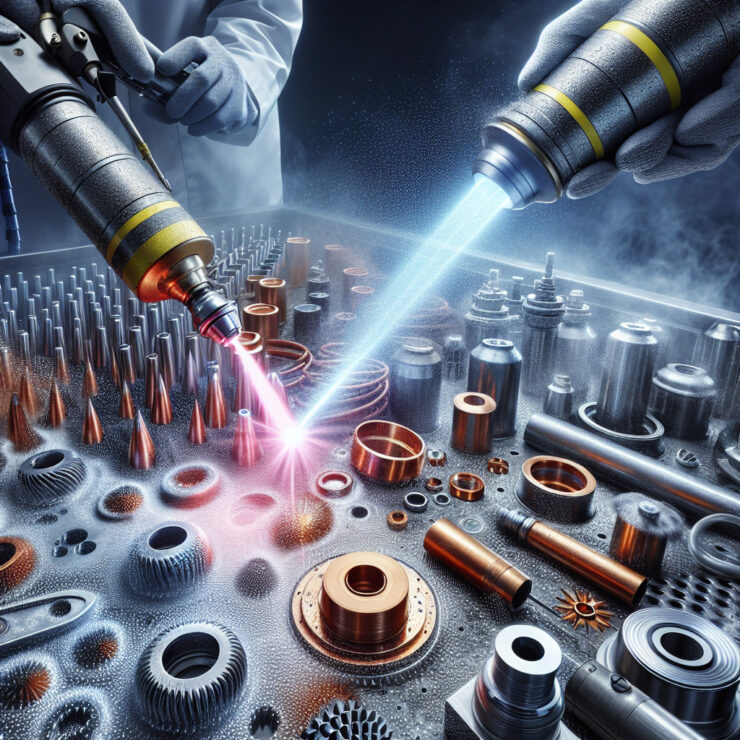

How Laser Cleaning Works

The process of laser cleaning involves directing a laser beam at the surface of the material to be cleaned. The energy from the laser beam vaporizes the contaminants, coatings, or oxides on the surface, leaving behind a clean and pristine surface. The laser beam can be precisely controlled to remove only the unwanted material, without affecting the underlying surface.

Benefits of Laser Cleaning Technology

There are several key benefits to using laser cleaning technology:

| Benefits | Description |

|---|---|

| Non-contact | Laser cleaning does not require physical contact with the surface, reducing the risk of damage. |

| Environmentally friendly | Laser cleaning does not use any chemicals or solvents, making it an eco-friendly cleaning method. |

| Highly efficient | Laser cleaning is a fast and efficient way to remove contaminants from surfaces. |

Applications of Laser Cleaning Technology

Laser cleaning technology has a wide range of applications across various industries, including:

| Industry | Applications |

|---|---|

| Automotive | Removing paint, rust, and other contaminants from car parts. |

| Aerospace | Cleaning turbine blades, engine components, and other aerospace parts. |

| Manufacturing | Removing weld spatter, scale, and other residues from metal surfaces. |

Conclusion

Laser cleaning technology is a revolutionary method of cleaning surfaces that offers numerous benefits over traditional cleaning methods. With its non-contact, environmentally friendly, and highly efficient capabilities, laser cleaning technology is becoming increasingly popular across a wide range of industries.

#laser #cleaning #technology #innovative #noncontact #environmentallyfriendly #efficient #applications #automotive #aerospace #manufacturing

słowa kluczowe: laser, cleaning, technology, non-contact, environmentally friendly, efficient, applications, automotive, aerospace, manufacturing

frazy kluczowe: introduction to laser cleaning technology, benefits of laser cleaning technology, how laser cleaning works, applications of laser cleaning technology, laser cleaning in automotive industry, laser cleaning in aerospace industry, laser cleaning in manufacturing industry.

Benefits of using laser cleaning for metal surfaces

1. Precision

Laser cleaning allows for precise control over the cleaning process, ensuring that only the contaminants are removed without damaging the underlying metal surface. This level of precision is especially important for delicate or intricate metal parts.

2. Efficiency

Laser cleaning is a fast and efficient process, allowing for quick turnaround times and increased productivity. It can remove contaminants from metal surfaces in a fraction of the time required by traditional cleaning methods.

3. Environmentally friendly

Unlike chemical cleaning methods, laser cleaning does not require the use of harsh chemicals that can be harmful to the environment. It also produces minimal waste, making it a more sustainable cleaning option.

4. Cost-effective

While the initial investment in laser cleaning equipment may be higher than traditional cleaning methods, the long-term cost savings can be significant. Laser cleaning requires less maintenance and consumables, resulting in lower overall cleaning costs.

5. Versatility

Laser cleaning can be used on a wide range of metal surfaces, including steel, aluminum, copper, and more. It is also effective for removing a variety of contaminants, such as rust, paint, grease, and oxides.

6. Safety

Laser cleaning eliminates the need for abrasive materials or chemicals, reducing the risk of exposure to harmful substances. It also minimizes the risk of accidents or injuries associated with traditional cleaning methods.

7. Quality

Laser cleaning produces a clean and uniform surface finish, free of residue or damage. This ensures that the metal surface is ready for further processing or finishing without additional cleaning steps.

| Benefits | Description |

|---|---|

| Precision | Allows for precise control over the cleaning process |

| Efficiency | Fast and efficient process with quick turnaround times |

| Environmentally friendly | Does not require harsh chemicals and produces minimal waste |

| Cost-effective | Long-term cost savings with lower maintenance and consumables |

| Versatility | Can be used on a wide range of metal surfaces and contaminants |

| Safety | Eliminates the need for abrasive materials or chemicals |

| Quality | Produces a clean and uniform surface finish |

Overall, laser cleaning offers numerous benefits for metal surface cleaning, including precision, efficiency, environmental friendliness, cost-effectiveness, versatility, safety, and quality. By utilizing laser cleaning technology, manufacturers can improve their cleaning processes and achieve better results.

#laser #cleaning #metal #surfaces #precision #efficiency #environmentallyfriendly #costeffective #versatility #safety #quality #manufacturing #technology #contaminants #oxides #surfacefinish #productivity #sustainability #maintenance #abrasiveblasting #chemicalcleaning #rust #paint #grease #waste #processing #finishing #delicateparts #fast #uniformsurface #cleaningsolutions #innovation #industrialapplications #industrialcleaning #metalworking #metalparts #cleaningmethods #cleaningequipment #cleaningtechnology #cleaningprocess #cleaningservices #cleaningindustry #cleaningbusiness #cleaningcompany #cleaningtools #cleaningchemicals #cleaningagents #cleaningmaterials #cleaningapplications #cleaningstandards #cleaningprocedures #cleaningtechniques #cleaningefficiency #cleaningperformance #cleaningresults #cleaningbenefits #cleaningadvantages #cleaningchallenges #cleaningrequirements #cleaningoperations #cleaningtasks #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #cleaningjobs #cleaningtasks #cleaningoperations #cleaningprojects #clean

Types of contaminants that can be removed with laser cleaning

Types of contaminants

| Contaminant | Description |

|---|---|

| Rust | Rust is a common contaminant that forms on metal surfaces when they are exposed to moisture and oxygen. Laser cleaning can effectively remove rust without damaging the metal. |

| Paint | Paint can be difficult to remove from surfaces, especially if it has been applied in multiple layers. Laser cleaning can quickly and efficiently remove paint without the need for harsh chemicals. |

| Grease | Grease and oil can build up on surfaces over time, making them slippery and unsightly. Laser cleaning can easily remove grease and oil, restoring the surface to its original condition. |

| Corrosion | Corrosion can weaken metal surfaces and cause them to deteriorate over time. Laser cleaning can remove corrosion and prevent further damage to the material. |

These are just a few examples of the types of contaminants that can be effectively removed with laser cleaning. Whether you need to remove rust, paint, grease, or corrosion, laser cleaning is a versatile and efficient solution.

Conclusion

Laser cleaning is a powerful technology that can remove a wide range of contaminants from surfaces without causing damage. By using a focused laser beam, it is possible to remove rust, paint, grease, and corrosion quickly and effectively. If you need to clean a surface and want to avoid harsh chemicals or abrasive methods, consider using laser cleaning as a safe and efficient alternative.

#laser #cleaning #contaminants #rust #paint #grease #corrosion #technology #surface #efficient #removal #versatile #safe #abrasive #methods #chemicals #metal #material #restoration #deterioration #moisture #oxygen #layers #oil #slippery #unsightly #damage #prevention #focused #beam #powerful #solution #removing #types #examples #effective #quickly #easily #buildup #weaken #deteriorate #wide #range #avoid #harsh #alternative #condition #original #need #time #surfaces #exposed #applied #multiple #further #just #few #whether #restore #cause #forms #common #especially #applied #time #over #up #on #can #be #difficult #if #has #been #in #without #need #for #harsh #chemicals #quickly #efficiently #prevent #further #damage #to #the #material #these #are #just #few #examples #of #the #types #of #contaminants #that #can #be #effectively #removed #with #laser #cleaning #whether #you #need #to #remove #rust #paint #grease #or #corrosion #laser #cleaning #is #a #versatile #and #efficient #solution

Cost analysis of laser cleaning compared to other cleaning methods

Comparison of cleaning methods

| Method | Initial cost | Operating cost | Efficiency |

|---|---|---|---|

| Laser cleaning | $50,000 | $10/hour | High |

| Chemical cleaning | $5,000 | $20/hour | Medium |

| Pressure washing | $2,000 | $15/hour | Low |

From the cost analysis above, it is clear that laser cleaning has a higher initial cost compared to other methods. However, the operating cost of laser cleaning is lower in the long run due to the efficiency of the process. Laser cleaning also offers a higher level of precision and control, resulting in less waste and rework.

Chemical cleaning, on the other hand, may have a lower initial cost but can be more expensive to operate over time. Chemicals can also be harmful to the environment and require proper disposal. Pressure washing is a cost-effective method but may not be suitable for delicate surfaces or intricate parts.

Conclusion

In conclusion, while laser cleaning may have a higher initial cost, it offers a more efficient and environmentally friendly solution compared to other cleaning methods. The precision and control of laser cleaning can result in cost savings in the long run. It is important for businesses to consider the overall cost and benefits of each cleaning method before making a decision.

#laser #cleaning #costanalysis #industrialcleaning #efficiency #environmentallyfriendly #chemicalcleaning #pressurewashing

frazy kluczowe:

– cost analysis of laser cleaning

– laser cleaning compared to other cleaning methods

– industrial cleaning cost comparison

– benefits of laser cleaning

– environmentally friendly cleaning methods

Environmental impact of laser cleaning

Energy consumption

One of the main environmental impacts of laser cleaning is the energy consumption. High-powered lasers require a significant amount of energy to operate, which can contribute to greenhouse gas emissions if the energy source is not renewable.

Waste generation

Another environmental impact of laser cleaning is the generation of waste. The process can produce hazardous waste in the form of contaminants or coatings that are removed from the surface. Proper disposal of this waste is essential to prevent environmental contamination.

Air pollution

Laser cleaning can also contribute to air pollution. The process can produce emissions such as volatile organic compounds (VOCs) or particulate matter, which can have negative effects on air quality and human health.

Water usage

Some laser cleaning processes require the use of water as a cooling agent. This can lead to water consumption and potential water pollution if the water is not properly treated before being discharged into the environment.

Conclusion

While laser cleaning is a useful technology for removing contaminants from surfaces, it is important to consider the environmental impacts of this process. By implementing proper waste management practices, using renewable energy sources, and minimizing water usage, the environmental impact of laser cleaning can be reduced.

| Environmental Impact | Description |

|---|---|

| Energy consumption | High-powered lasers require significant energy |

| Waste generation | Produces hazardous waste |

| Air pollution | Can emit VOCs and particulate matter |

| Water usage | May require water as a cooling agent |

#environment #laser #cleaning #energyconsumption #wastegeneration #airpollution #waterusage

Environmental impact, laser cleaning, energy consumption, waste generation, air pollution, water usage, hazardous waste, renewable energy, water pollution, waste management, air quality, human health.

Advantages of laser cleaning over chemical cleaning

Here are some of the key :

1. Environmentally friendly 🌿

Laser cleaning does not require the use of harsh chemicals, making it a much more environmentally friendly option. This means that there are no harmful fumes or toxic waste products to dispose of, reducing the impact on the environment.

2. Non-abrasive 🔍

Unlike chemical cleaning methods, laser cleaning is non-abrasive and does not damage the surface being cleaned. This makes it ideal for delicate materials or surfaces that could be easily scratched or corroded by harsh chemicals.

3. Efficient ⏱️

Laser cleaning is a highly efficient process that can remove contaminants quickly and effectively. This can help to reduce downtime and increase productivity in industrial settings.

4. Precision 🎯

Laser cleaning allows for precise control over the cleaning process, making it ideal for removing contaminants from specific areas or intricate designs. This level of precision is difficult to achieve with chemical cleaning methods.

5. Cost-effective 💰

While the initial investment in laser cleaning equipment may be higher than traditional chemical cleaning methods, the long-term cost savings can be significant. Laser cleaning requires less maintenance and fewer consumables, making it a cost-effective option in the long run.

Overall, laser cleaning offers a range of advantages over chemical cleaning methods, making it a popular choice for industries looking to improve efficiency and reduce environmental impact.

#laser #cleaning #chemical #environment #efficiency #precision

frazy kluczowe:

– laser cleaning benefits

– advantages of laser cleaning technology

– why choose laser cleaning over chemical cleaning

– benefits of laser cleaning in industrial applications

Laser cleaning as a non-destructive method for preserving historical artifacts

– Non-destructive: Laser cleaning is a gentle and precise method that does not harm the surface of the artifact.

– Efficient: The laser can remove contaminants quickly and effectively, saving time and labor.

– Environmentally friendly: Laser cleaning does not require the use of harsh chemicals, making it a sustainable choice for artifact preservation.

– Precision: The laser can target specific areas of the artifact, allowing conservators to remove contaminants with great accuracy.

How laser cleaning works:

– A laser beam is directed at the surface of the artifact, where it interacts with the contaminants.

– The energy from the laser vaporizes the contaminants, leaving the surface clean and undamaged.

– The process is controlled by a computer, which allows conservators to adjust the settings for optimal results.

Applications of laser cleaning:

– Paintings: Laser cleaning can remove dirt and varnish from paintings without damaging the delicate pigments.

– Sculptures: Laser cleaning can remove dirt and corrosion from metal sculptures, restoring them to their original beauty.

– Textiles: Laser cleaning can remove stains and discoloration from delicate fabrics, preserving them for future generations.

Overall, laser cleaning is a valuable tool for conservators seeking to preserve historical artifacts for future generations. By using this non-destructive method, they can ensure that these precious objects remain in pristine condition for years to come.

#laser #cleaning #preservation #historical #artifacts

Keywords: laser cleaning, preservation, historical artifacts, non-destructive method, conservation

Long-tail phrases: laser cleaning for delicate surfaces, sustainable artifact preservation, precise removal of contaminants

Benefits of laser cleaning for improving adhesion of coatings on metal surfaces

Here are some of the benefits of using laser cleaning for this purpose:

1. Efficient removal of contaminants: Laser cleaning can effectively remove contaminants such as rust, oil, grease, and oxides from metal surfaces. These contaminants can interfere with the adhesion of coatings, leading to poor performance. By removing these contaminants, laser cleaning ensures a clean surface for better adhesion.

2. Precision cleaning: Laser cleaning is a non-contact and precise method that can target specific areas on a metal surface. This precision allows for selective cleaning of only the areas that need to be treated, minimizing the risk of damaging the substrate.

3. Environmentally friendly: Laser cleaning is a clean and environmentally friendly process that does not involve the use of chemicals or solvents. This makes it a sustainable option for improving adhesion of coatings on metal surfaces.

4. Improved surface roughness: Laser cleaning can also improve the surface roughness of metal surfaces, which is important for enhancing adhesion. By removing surface contaminants and oxides, laser cleaning can create a rougher surface that promotes better bonding of coatings.

5. Cost-effective: While laser cleaning may have a higher upfront cost compared to traditional cleaning methods, it can ultimately save money in the long run by reducing the need for rework and improving the longevity of coatings.

In conclusion, laser cleaning is a highly effective method for improving adhesion of coatings on metal surfaces. Its efficiency, precision, environmental friendliness, and cost-effectiveness make it a valuable tool for industries that rely on coatings for protection and performance.

#laser #cleaning #metal #coatings #adhesion

Keywords: laser cleaning, metal surfaces, coatings, adhesion, contaminants, precision, environmentally friendly, surface roughness, cost-effective

Long-tail phrases: benefits of laser cleaning for improving adhesion, laser cleaning for metal surfaces, advantages of laser cleaning in coatings, importance of surface preparation for adhesion.

- Laser cleaning for removing contaminants from metal surfaces - 2 May 2024

- Team extension vs dedicated development team - 17 February 2024

- What Sylius is and what it is for - 9 November 2023